UPVC Pipes & Fittings in Ahmedabad

Highlight of the Products- Suitable for potable water transportation

- High impact strength and durability

- UV stabilised, ensuring protection from direct sunlight

- Light weight and easy to install

- Cost-effective and maintenance-free

- No corrosion, thus uncompromised water quality

- Excellent resistance to chemicals

- Smooth internal surface

- Fire-resistant and self-extinguishing

- Energy saving and 100% leak-proof

- Lowest bacterial growth

- Unaffected by chlorine in water

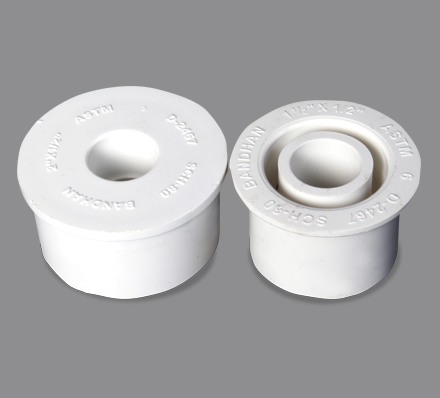

Product Range and Standards

Swipe to left or right to see the full table

| Variants | sizes available | pipe | fittings |

|---|---|---|---|

| Schedule 40 | 1⁄2” – 6” | ASTM D 1785 | STM D 2466 |

| Schedule 80 | 1⁄2” – 6” | ASTM D 1785 | STM D 2467 |

Swipe to left or right to see the full table

Temperature Correction or Derating Factors

Swipe to left or right to see the full table

| Operating Temperature | ⁰F | 70 | 80 | 90 | 100 | 110 | 115 | 120 | 125 | 130 | 140 |

| ⁰C | 21 | 27 | 32 | 38 | 43 | 46 | 49 | 52 | 54 | 60 | |

| PVC 1120 | 1.00 | 0.88 | 0.75 | 0.62 | 0.50 | 0.45 | 0.40 | 0.35 | 0.30 | 0.22 | |

Note:

1) PVC 1120 is the recommended grade of UPVC materials in ASTM D 1784 & 1785 having Hydrostatic Design Stress of 14Mpa or 2000 PSI

2) To obtained working pressure at a different operating temperature, the above-mentoned working pressure should be multiplied by the respective correction or derating factor. For example, the working pressure for 2" X Schedule-80 pipes at 110⁰F or 43⁰C should be 28.0 X 0.5 or 14.0kg/cm2